Home » Slip Ring Manufacturer

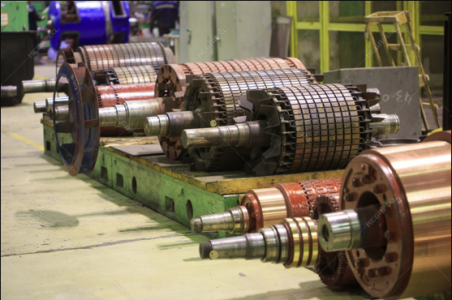

Slip Ring Manufacturing & Supply

Collector Ring Rebuild, Complete New or Repair

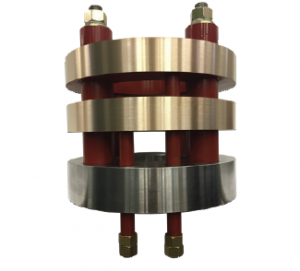

Slip rings are electromechanical interfaces used in the transmission of electrical current from a stationary unit to a rotating assembly. They will operate in one of two ways. One method requires the center core to remain stationary while the brushes and housing rotate around the slip ring. The alternative option occurs when the brushes and housing remain stationary while the center core with the slip ring rotates.

EMCC has extensive experience manufacturing slip ring assemblies for various industrial applications. Our slip rings can be found in vital machinery and rotating equipment worldwide. We can manufacture slip rings completely new, based on OEM specs, repair, or retrofit an existing assembly.

EMCC Quality Standards Controlled to ISO 9001:2015

Slip Ring Capabilities

- Slip Ring Manufacturing

- Slip Rings for Asynchronous Wound Motors

- Power Slip Rings for Wind Generators

- Power Slip Rings for Hydro Power Generators

- Extensive Range Slip Ring Type and Size Capabilities

- Re-fill or Complete New

- Slip/Collector Ring Re-insulation

- Slip/Collector Ring Repair

- Finished Slip Ring dielectric testing

- Navel Bronze, Brass, Stainless Steel, Copper

- Molded Slip Ring Conversions

- Split Ring Slip Rings

- Various Insulation Types

- Round Leads, Flat Leads, Spilt Ring Design

- Dust Grooves, Keyways, Cooling Holes/Vents

- Slip Ring Repair/Re-insulate (where applicable)

- High Power Slip Rings

- 24/7 Emergency Repair Service

Slip Ring Applications

EMCC Slip Rings are used in a wide variety of sectors throughout North America; most notably in the Energy, Transportation and process industries. Our equipment, materials, and experience are what set us apart from other suppliers. For nearly 30 years, rotating equipment industries have come to depend on EMCC for consistent service, delivery, and quality.

Stainless Steel Rings

Stainless Steel Ring material is chosen based on Slip Ring current and application requirements.

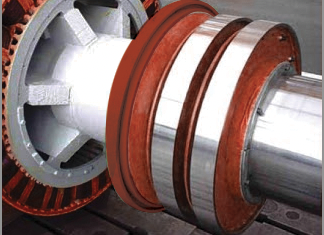

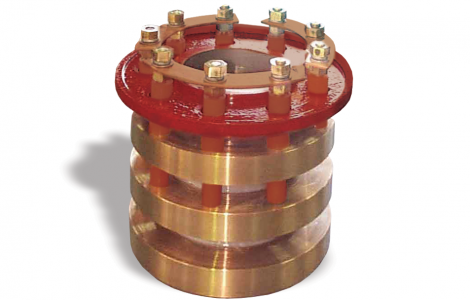

Copper Alloy Rings

Naval Bronze Alloy Rings

Naval Bronze is a high-quality semi-conductive Slip Ring material that is more cost-conscious than copper. Material is chosen based on Slip Ring current and application requirements.

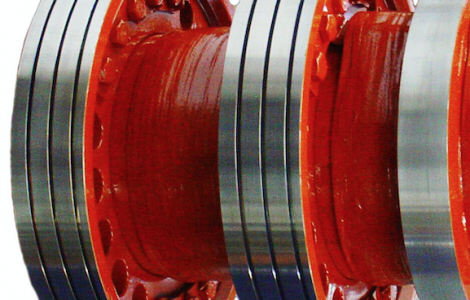

Dust Grooving

EMCC Slip Rings can be manufactured with, or without helical grooves.

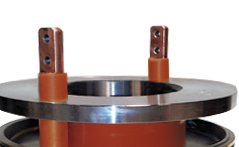

Lead Styles

- Rectangular

- Round

- Threaded w/ Lock Nuts

Lead Insulation Types

- Phenolic

- Fiberglass

- Mica

Slip Ring Lead Materials

Slip Ring lead materials are chosen based on their electrical/thermal conductivity and application requirements.

- Bronze

- Copper Alloy

24/7 Slip Ring Manufacturing

The Electric Motor Coil Company specializes in the manufacturing, rebuild, and repair of high-quality Slip Rings / Collector Rings. We offer 24/7 Emergency Service to our valued customers.