Home » Commutator Manufacturer » Glass Banded Commutators

Glass Banded Commutators

Commutators...We Do It Better.™

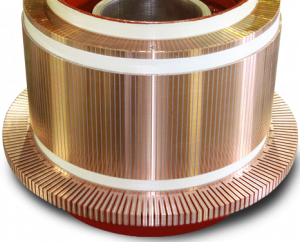

EMCC manufactures various types and sizes of commutators, including Glass Banded Commutators. We can rebuild, re-fill, repair to OEM specifications. With over 35 years of experience manufacturing Glass Banded commutators; we have built a reputation for consistent quality and reliability.

Typical Glass Banded Commutators differ from V-ring style Commutators. V-ring Commutators have steel V-rings insulated with mica that holds the copper & mica assembly together while under pressure. Since the pressure is only applied at both ends of the segment pack, vibration and lifting can occur if the copper bars required are to be quite long.

Glass Banding

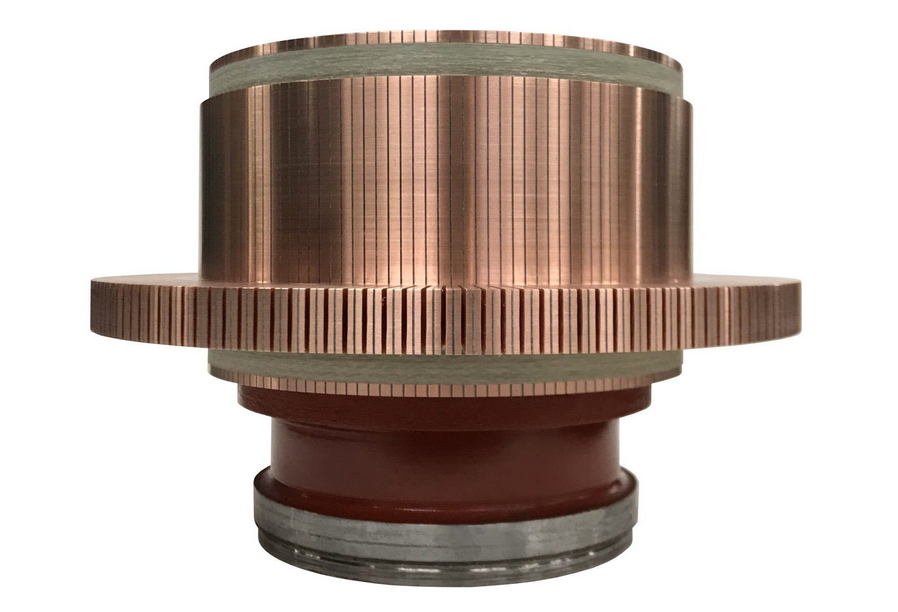

In a Glass Banded Commutator construction, resin-glass banding (comprised of high tensile glass yarns) is applied under tension to cut grooves along the surface of the copper bars. The resin glass bands are cured. Therefore, keeping the copper segments compressed and held in place by the resin glass bands. The number of glass bands and their placement can vary depending on bar length, brush placement, and overall motor design.

Capabilities

EMCC has developed custom tooling and dedicated equipment specifically for manufacturing Glass Banded Commutators. We offer our customers Multi-Banded Commutators, Hybrid V-Ring & Glass Banded Commutators, various riser types including Inserted, Solid and Lap-Joint.

Glass Banded to V-ring Conversions

EMCC can manufacture Shrink-fitting Glass Banded Commutators to a dovetailed v-bound commutator with a steel V-ring style core (where applicable).

Shrink-Fit Glass Banded Commutators are advantageous in certain use cases where overall weight and airflow are a consideration. However, in some applications, they carry more disadvantages than advantages. Glass Banded Commutators are difficult to repair, cannot be re-insulted, and can be susceptible to failure in high heat and contamination environments due to the banding.

Some countermeasures can be applied to the banding in the final stages of construction, but often these are not enough. In these situations, a glass banded to V-ring conversion may be considered. Converting a Glass-Banded Commutator to a V-Bound / V-ring type Commutator is not always a viable or possible solution. Many factors must be considered before attempting this type of re-construction for an aftermarket application. Weight, copper segment length, armature airflow, venting, and cost are all factors that must be examined by our qualified engineers.

24/7 Commutator Manufacturing

When that call comes in – we are here to help at a moment’s notice. Costs associated with unplanned downtime can be immense. For this reason, The Electric Motor Coil Company offers 24/7 Emergency Service to our valued clients. We are fully committed to getting you the quality Commutators and motor/generator windings you need – with the fastest emergency turn-around times in the industry.

EASA Association

The Electric Motor Coil Company is an associate member of EASA.

The Electrical Apparatus Service Association, Inc. (EASA) is an international trade organization for the electromechanical industry, and is active globally in almost 70 countries. Associate members are manufacturers and suppliers of equipment, parts, services and materials used, serviced or sold by Active members.