Home » Commutator Manufacturer » V-Ring Commutator Manufacturer

V-Ring Commutator Manufacturing

Commutators...We Do It Better.™

At EMCC/Thistle Industries, we manufacture and supply more V-Ring Commutators than any other type of Commutator.

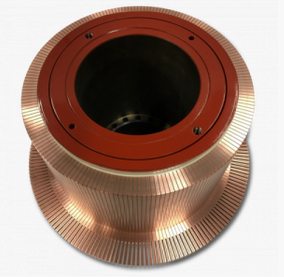

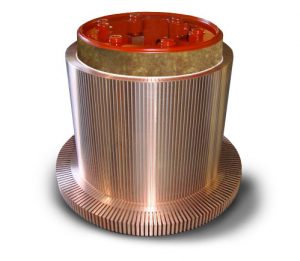

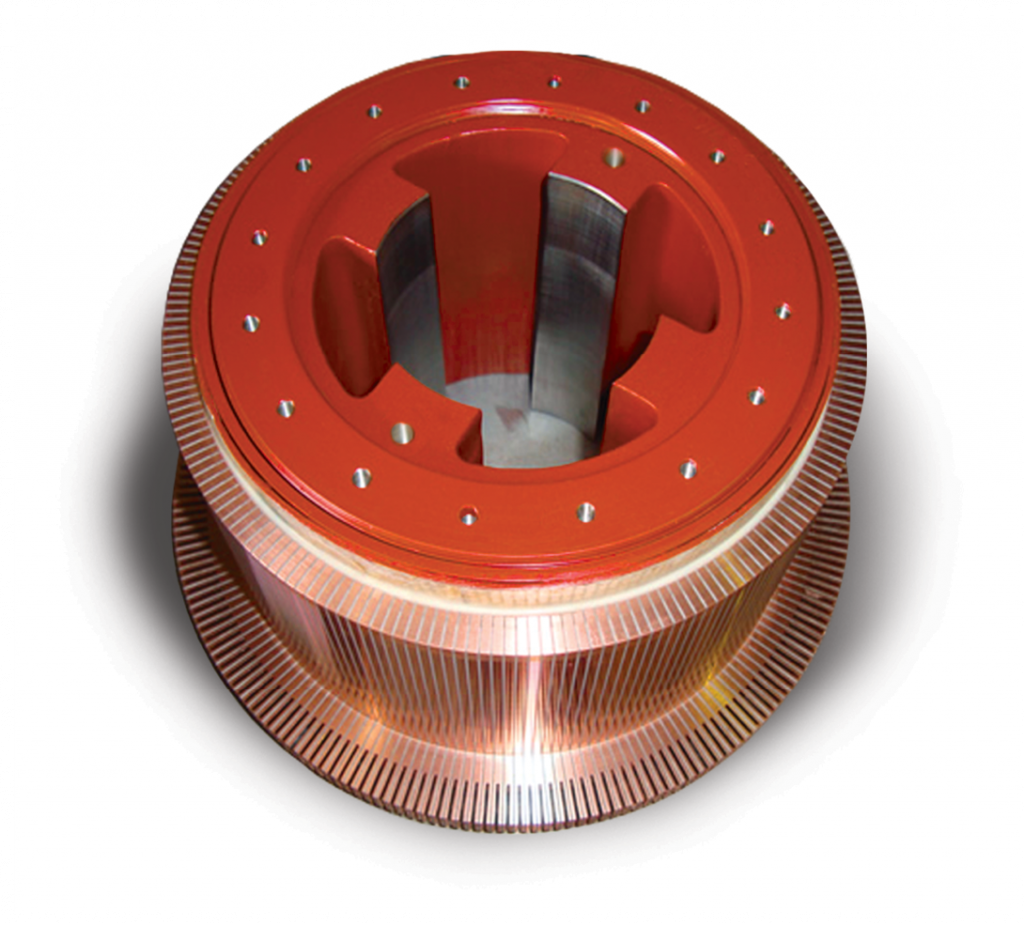

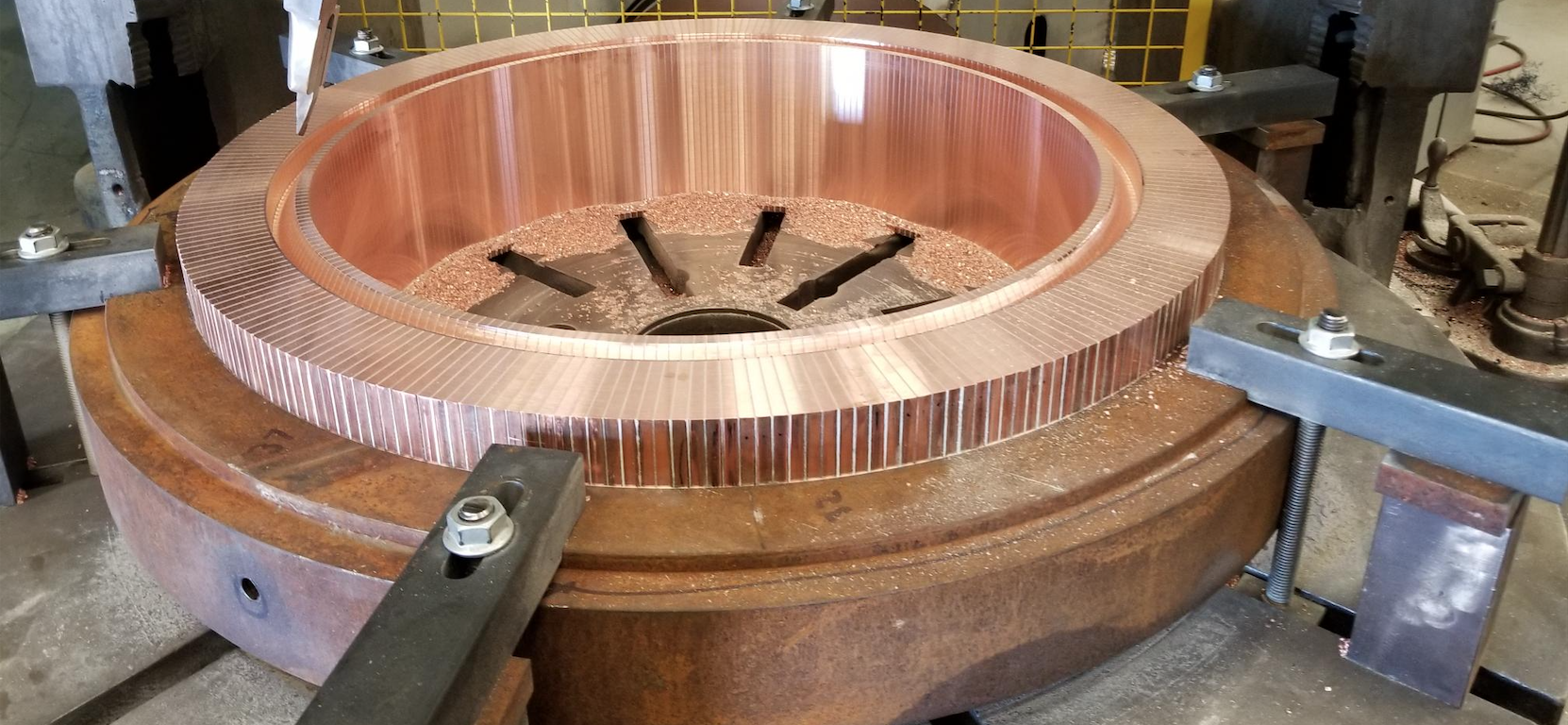

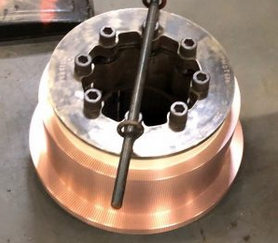

Most commonly, our Commutators are used in the manufacture, repair and rewinding of DC Generators and Motors. V-ring Commutators are composed of copper bars and a steel core that is insulated and electrically isolated from each other by segments of mica. Insulated steel V-rings are forced together under pressure on the dovetails machined into the commutator. Nuts or bolts are then tightened on the steel hub while under intense pressure – Therefore, locking the copper mica assembly in place on the insulated steel core.

The bar segments of our Commutators are made of high silver content copper alloy (for better conductivity) and are separated from each other by high-quality mica insulation that remains stable with heated temperature and compression. Slots are expertly cut in the riser based on your coil specifications.

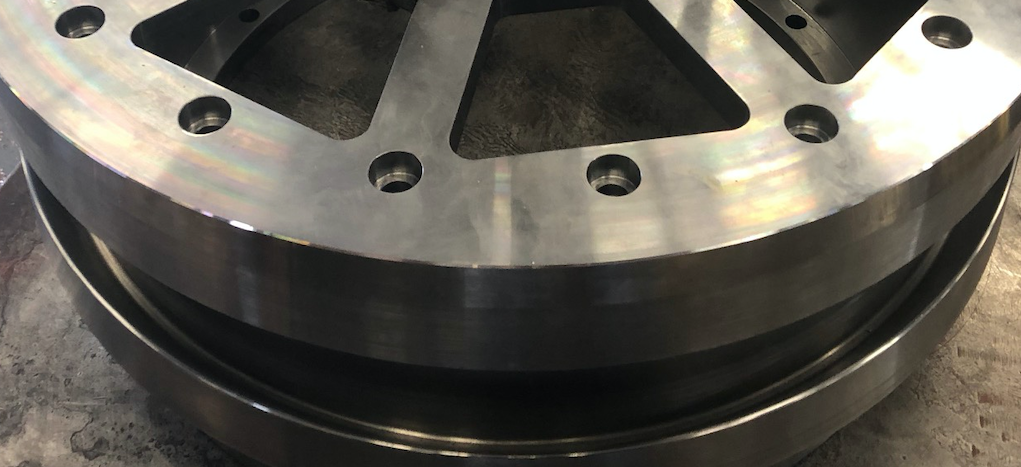

Our V-ring commutators come in a wide variety of types and sizes. Some V-ring commutators may have an inserted riser with a vented steel core, while others may have a stepped bore with a key-way alignment. Often, molded commutators are re-engineered and converted into a v-ring style Commutator with a re-usable steel core. Having a re-usable steel core allows for more economical repairs and replacements (Commutator Refill) in the future.

24/7 Commutator Rebuild

When Commutators fail, EMCC has the expertise, capability and manpower to work around the clock – to manufacture the Commutators and coils you need. Our 24/7 Emergency “Rush Order ” production capability allows us to deliver unmatched Commutator quality, with the best turnaround times in the industry. Often delivering coils within 24-hours and commutators between 24-48 hours – depending on the size, type and quantity.

Commutator Manufacturing Capabilities

- 35+ Years Experience

- Re-fill or Complete New Steel Parts

- High Silver Content Alloy 116 Copper Bar Material.

- Vented Cores, Keyways, Nuts, Bolts, & Stepped Bores.

- Commutator conversions

- Seasoned and 100% Tested

- Emergency Rebuild Service

- Delivery Worldwide

- All Riser Types

- Commutator Sizes from 3″ to 60″ in diameter.

- Manufacturing Quantities from 1 to Unlimited

- Riser Slots Custom Cut to Suit

Comprehensive Commutator Solutions

In-House Machine Shop Capabilities

Commutator Manufacturing

Whether repairing, replacing or re-building, your Commutator – we have the machining capabilities to get the job done right. This includes broaching keyways, threading, welding (arc, mig, & tig), boring & milling, cooling holes, vented bores, and stepped bores. Our machines range from boring mills, lathes, CNC lathes, CNC milling machines, broaching machines, automated shearing, brazing, to burn-out ovens.

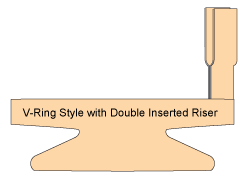

Commutator Riser Types

- Single Slot Solid Risers

- Double Slot Solid Risers

- Risers with Equalizer Slots

- Inserted Risers

- Double Inserted Risers

Lock-Nut Commutators

EMCC Manufactures Commutators of all shapes, sizes and design styles, which include:

- Bolted

- Vented Bores

- Stepped Bore

- Cooling Holes

- Threaded Balance Weight Holes

- Keyways

- Balancing Plates

- Reverse Dovetails

Mica Insulated V-rings

Mica v-rings are used as insulation in V-Ring Commutator manufacturing. Mica V-rings can be produced in one-piece or two-piece designs. These electrical insulating rings are made of Micanite, which is heated and then molded to specification.

24/7 Commutator Manufacturing

When that call comes in – we are here to help at a moment’s notice. Costs associated with unplanned downtime can be immense. For this reason, The Electric Motor Coil Company offers 24/7 Emergency Service to our valued clients. We are fully committed to getting you the quality Commutators and motor/generator windings you need – with the fastest emergency turnaround times in the industry.

Secure Commutator Packaging

Shipping globally by land, air or sea. Our shipping department custom-builds the proper packaging solutions for, the products we deliver. You can trust that your Commutators and Coils will arrive on time, on budget, and in perfect condition. Packaging solutions may include crates, encapsulated foam packing or water and humidity sealed foil.