Home » Field, Rotor & Interpole Coil Manufacturer

Built For Winders ™

Field, Interpole, Salient Pole & Rotor Pole Coils

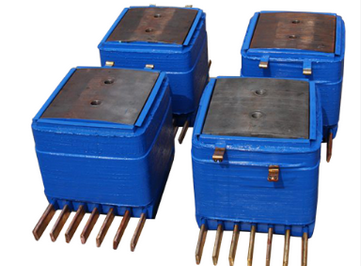

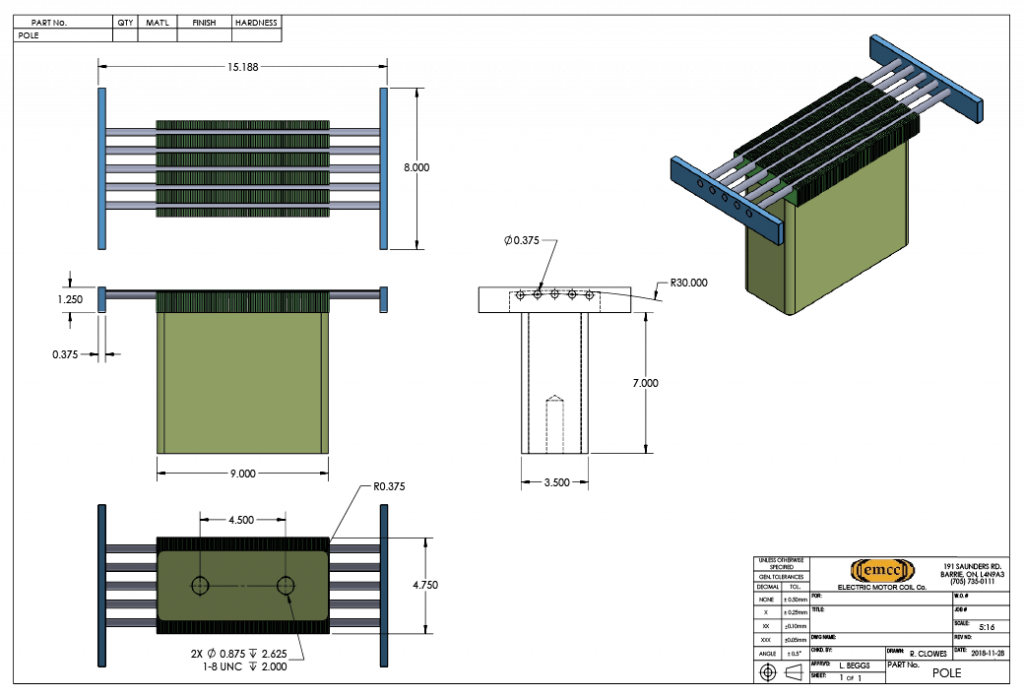

Rotor Pole Coils are critical components to power generation industries. EMCC has extensive capabilities in the manufacturing repair, and rebuilding of field, interpole and Rotor Coils. We have experience repairing coil sets of various sizes and types; from numerous manufacturers.

EMCC can manufacture high-volume Rotor Pole Coils for Induction Generators – from raw copper to final product. Our automated and OEM dedicated machinery allows us to mass-produce Rotor Pole Coils quickly and efficiently; meeting all OEM cost, quality, and delivery requirements.

The Electric Motor Coil Company has the cranes and automated pull/loop machinery in place required to manufacture large Field, Salient Pole, Inter-pole, and Rotor Coil sets.

Our quality control process ensures compression and makes sure every coil is perfect and fully cured under pressure. We built steel forms, instead of plywood forms to ensure exacting measurements and that every coil is the same.

Coil Capabilities

- Rotor Coils For Induction Generators

- Shunt Wound Field Coils

- Series Field Coils

- Interpole Coils

- Push Through Rotor Coils

- Two Turn Rotor Coils

- Re-build Edge-wound Coils

Salient Poles - Refurbish Edge-Wound Coils for extended service life