Home » Traction Motor Coil Manufacturing

Traction Motor Coil Manufacturer

Global Supplier of Traction Motor Coils / Windings

EMCC is committed to becoming your preferred supplier of Traction Motor Coils.

Proven Traction Coils - Reliable Delivery

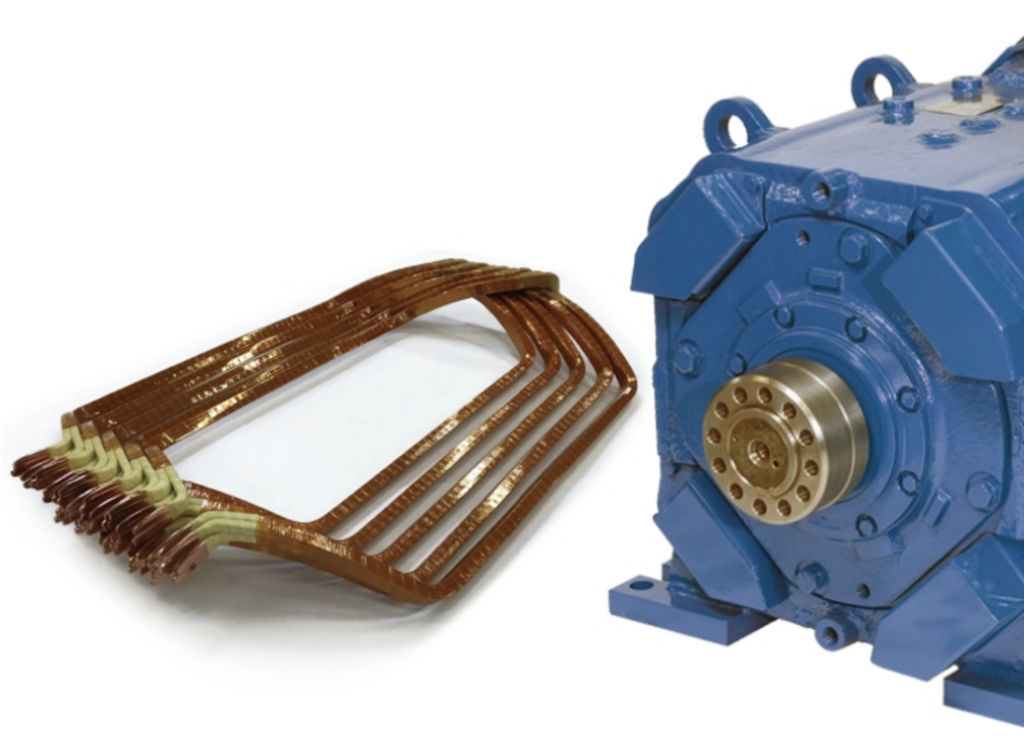

The Electric Motor Coil Company services motor OEM’s and Traction Motor repair shops throughout the world. When it comes to Traction Motor Coils, computer-aided design just doesn’t go far enough. Our Traction Motor Coils are developed on an actual armature to ensure that the fit and function of every coil is perfect. Globally competitive costing, automated coil manufacturing, dedicated tooling, quality control systems, and expedited deliveries make the difference.

If Our Customers Need It, EMCC Can Build It.

- Replacement Coils for EMD & GE Traction Motors

- Windings for Traction Auxiliary Motors

- AC Traction Motor Coils

- Coils for Linear Induction Motors

- Windings for DC Traction Motors

EMCC supplies Traction Motor Coils and Winding supplies to OEMs and rotating equipment repair shops globally. EMCC Traction Motor Windings can be found in:

- Class-1 Railways

- Off-Road Mining Vehicles

- Mass Transit

- Heavy Rail

- Large Mill Motors

- Diesel Electric Drilling Rigs

- Wind Turbines

Stocking of Traction Motor Winding Kits

We offer Traction Motor Winding Kits with same-day shipping. Winding Kits can be developed to individual customer specifications when required.

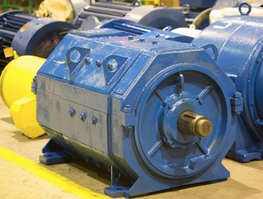

Traction Motor Windings For Off-Road Mining Vehicles

AC Diesel-Electric Drive systems with traction Motors offer increased efficiency. Traction Motors have a high speed and torque power-to-weight ratio.

EMCC Traction Motor Windings are used in Traction Wheel Motors for off-road mining vehicles globally.

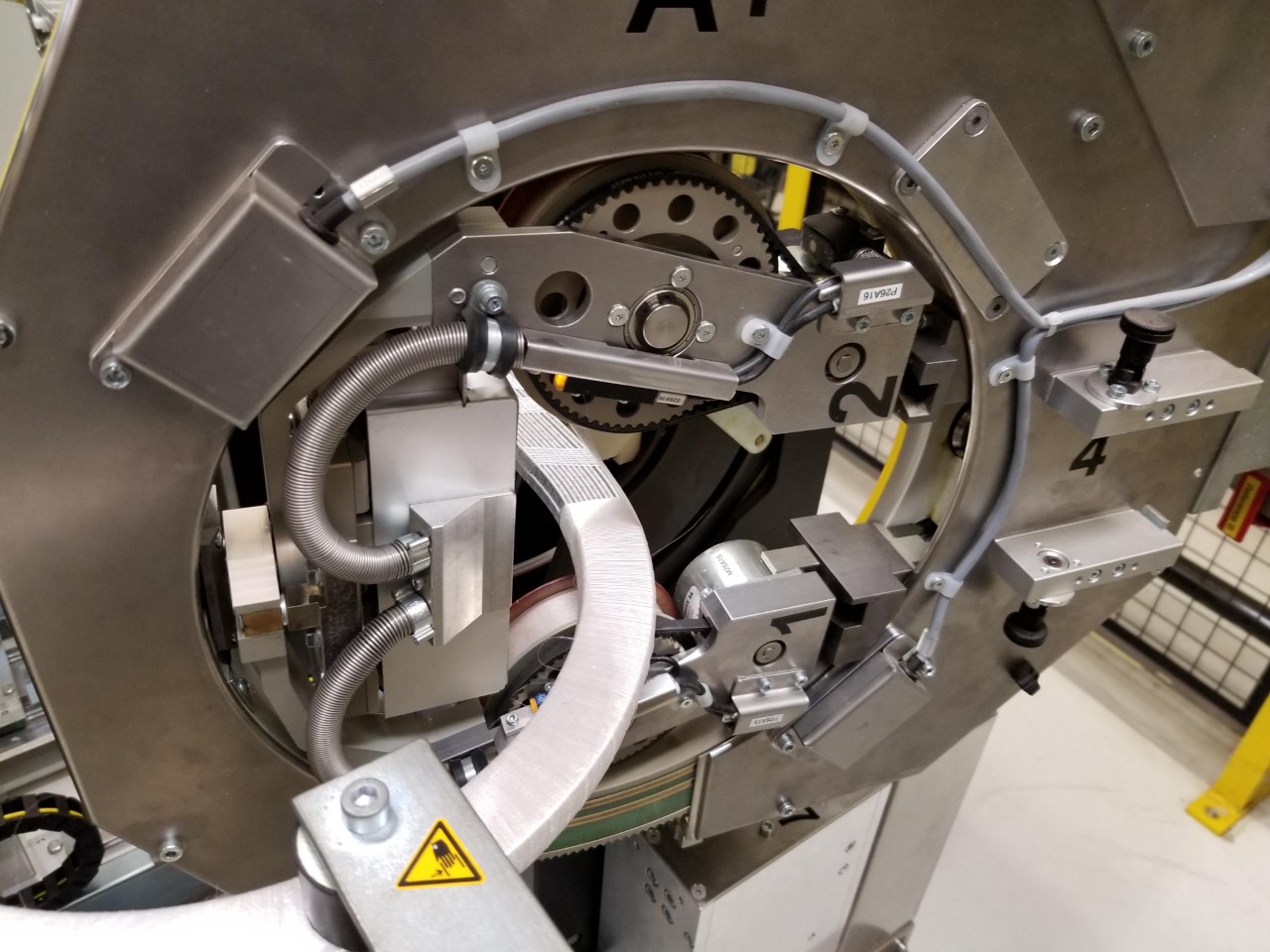

Linear Induction Coils

- Replacement Coils for EMD & GE Traction Motors

- Coils for Traction Auxiliary Motors

- AC Traction Motor Coils

- Coils for Linear Induction Motors

- Windings for DC Traction Motors

Innovate & Automate

If you need it, we can build it. EMCC brings automated coil manufacturing technology to any Traction Winding Set. EMCC technicians and engineers are at the forefront of today’s coil manufacturing industry. We have the extraordinary ability to innovate and automate any project we work on.

Documentation & Traceability

- All Coil manufacturing is done in compliance with our quality procedures.

- Process documents travel with every coil through each manufacturing stage.

- Material traceability is complete with every Traction Motor Winding order.

PERFECTLY FITTING COILS

Reliable, Cost-effective Traction Motor Coils with Fast & Easy Installation. Each Winding set that we build is first developed using computer-aided design, to ensure that your coils fit perfectly, every time. Dimensional checks and quality control stop/ checkpoints are conducted throughout the entire manufacturing process.