High-Volume Winding For OEM's

One of EMCC’s “value-added” supplier philosophies; “If our customers need it, we can build it”. This philosophy has significantly improved our ability to take problems faced by motor & Generator OEM’s and turn them into customized solutions.

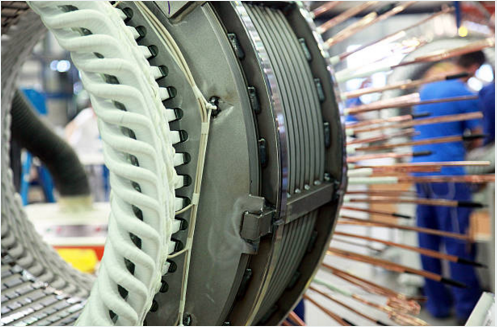

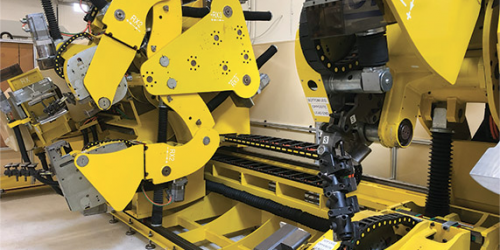

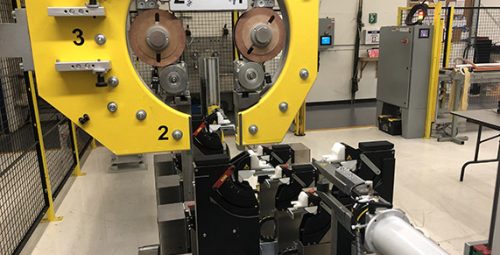

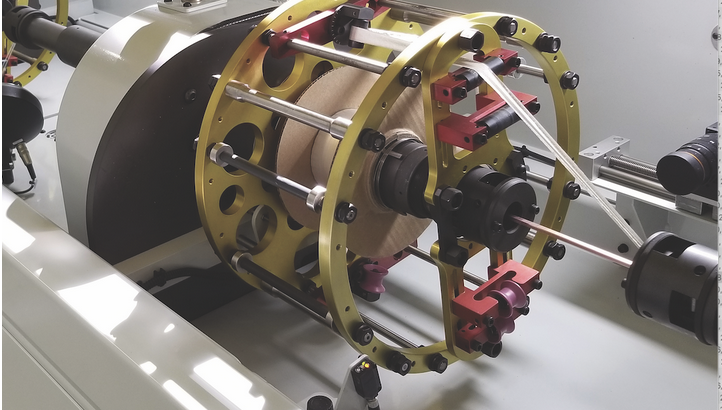

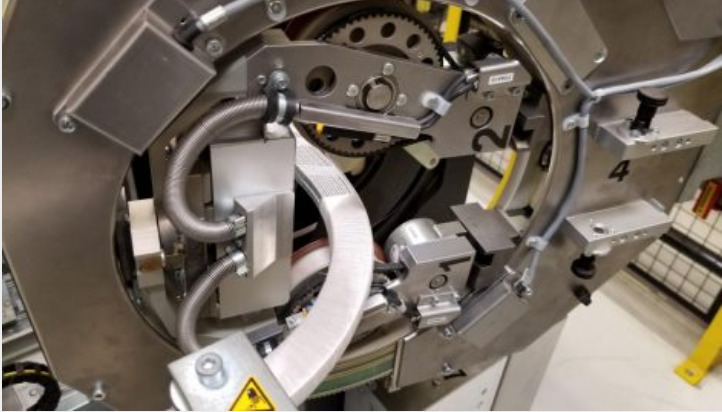

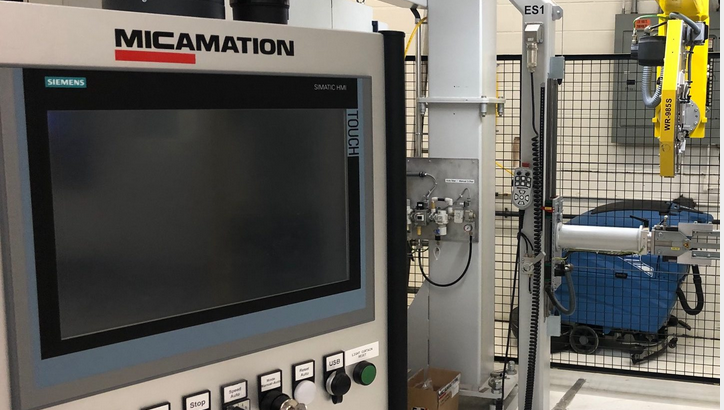

For this reason, EMCC has an in-house winding department (specifically for OEM’s) capable of high-volume winding and repairs. EMCC has created dedicated OEM automated machinery, tooling and dedicated steel molds.

Our large-scale automated manufacturing processes, combined with duplicate production machines, ensure uninterrupted delivery of OEM coils and wound motors/ generators. (EMCC does not rewind aftermarket Motors and Generators.)